Abavelisi babonelela ngempompo yegiya ezenzekelayo koomatshini behardware yempompo yegiya ye-hydraulic

Ingcaciso yeMveliso

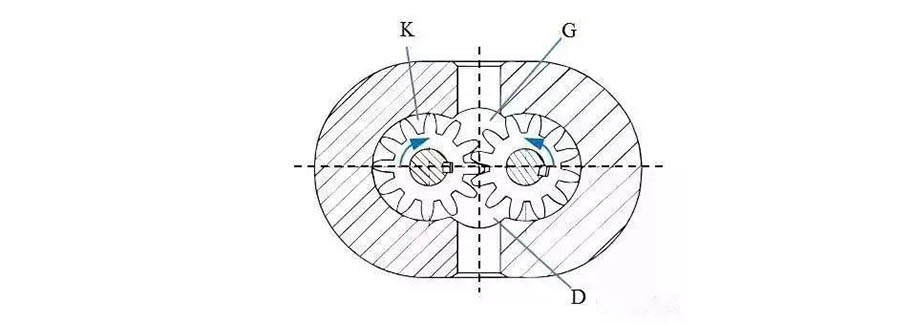

I-cylinder yezinyo eliphezulu kunye nobuso bokugqibela kumacala omabini eegiya ezidibanisa enye kwenye zikufutshane nodonga lwangaphakathi lwe-casing yempompo, kunye nothotho lwemingxuma yokusebenza etywiniweyo K ivalwe phakathi kwendawo nganye yezinyo kunye nodonga lwangaphakathi lwe. ingxowa.I-D kunye ne-G cavities eyahlulwe ngamazinyo e-meshing gear ligumbi lokufunxa kunye negumbi lokukhupha elidityaniswe nezibuko lokufunxa kunye nezibuko zokukhupha zempompo, ngokulandelanayo.Njengoko kubonisiwe (i-meshing yangaphandle).

Xa igiya ijikeleza kwicala eliboniswe kumzobo, umthamo wegumbi lokufunxa u-D unyuka ngokuthe ngcembe kwaye uxinzelelo luyehla ngenxa yamazinyo e-meshing ephuma ngokuthe ngcembe kwimeko ye-meshing.Phantsi kwentshukumo yomahluko woxinzelelo phakathi koxinzelelo lomphezulu wolwelo wedama lokufunxa kunye noxinzelelo oluphantsi kumngxuma D, ulwelo lungena kwigumbi lokufunxa D ukusuka kwidama lokufunxa ngombhobho wokufunxa kunye nezibuko lokufunxa lempompo.Emva koko ingena kwindawo evaliweyo yokusebenza K, kwaye iziswe kwigumbi lokukhupha G ngokujikeleza kwegiya.Ngenxa yokuba amazinyo ezi giya zimbini zingena ngokuthe ngcembe kwimeko yokuhlangana ukusuka kwicala elingasentla, amazinyo egiya enye ngokuthe ngcembe athatha indawo yokuhlangana yenye igiya, ukuze umthamo wegumbi lokukhupha elibekwe kwicala elingasentla unciphe ngokuthe ngcembe, uxinzelelo lwamanzi kwigumbi luyanda, ngoko ke impompo ikhutshwe kwimpompo.I-port yokukhupha ikhutshwe ngaphandle kwempompo.Isixhobo sijikeleza ngokuqhubekayo, kwaye iinkqubo zokufunxa ezikhankanywe ngasentla kunye nokukhutshwa ziqhutyelwa ngokuqhubekayo.

Eyona ndlela isisiseko yempompo yegiya kukuba iigiya ezimbini zobukhulu obufanayo obunemesh kwaye zijikeleza enye kwenye kwicasing efakwe ngokuqinileyo.Ingaphakathi le-casing lifana ne "8" imilo, kwaye iigesi ezimbini zifakwe ngaphakathi.Indlu iyalingana.Izinto ezivela kwi-extruder zingena kumbindi weegiya ezimbini kwizibuko lokufunxa, zizalise isithuba, zihambe ecaleni kwecasing ngokujikeleza kwamazinyo, kwaye ekugqibeleni zikhuphe xa amazinyo amabini enemesh.

Iimbonakalo

1.Ukusebenza kakuhle kokuzilungiselela.

2. Ulwalathiso lokufunxa kunye nokukhutshwa luxhomekeke ngokupheleleyo kwicala lokujikeleza kwe-shaft yepompo.

3. Isantya sokuhamba kwempompo ayinkulu kwaye iyaqhubeka, kodwa kukho i-pulsation kwaye ingxolo inkulu;isantya sokubetha yi-11% ~ 27%, kwaye ukungalingani kwayo kunxulumene nenani kunye nokumila kwamazinyo egiya.Ukungalingani kweegiya ze-helical kuncinci kunezo ze-spur gears, kunye nomntu Ukungalingani kwe-helical gear kuncinci kune-helical gear, kwaye inani elincinci lamazinyo, likhulu izinga lokubetha.

4. Ukuhamba kwethiyori kunqunywe ubungakanani kunye nesantya seendawo zokusebenza, kwaye akunanto yakwenza noxinzelelo lokukhutshwa;uxinzelelo lokukhupha luhambelana noxinzelelo lomthwalo.

5. Isakhiwo esilula, ixabiso eliphantsi, iindawo ezimbalwa zokugqoka (akukho mfuneko yokuseta i-valve yokufunxa kunye nokukhupha), ukuchasana kwempembelelo, ukusebenza okuthembekileyo, kwaye kunokudibaniswa ngokuthe ngqo kwi-motor (akukho mfuneko yokuseta isixhobo sokunciphisa).

6. Kukho iindawo ezininzi zokungqubuzana, ngoko ke akufanelekanga ukukhupha ulwelo oluqulethe amasuntswana aqinileyo, kodwa ukukhupha ioli.